Aluminium is the most abundant metal in the earth’s crust, and yet the light metal was discovered only a couple of centuries ago. Today, powered by the drive to sustainable development, aluminium is everywhere – beverage cans, window frames and food packaging. At the same time, the European Union is creating a basis for a transition from a linear to a circular economy.

Thanks to its unique physical properties and infinite recyclability, aluminium will be an essential material in the future resource-efficient economy. With new opportunities emerging every year for the aluminium industry, this is proof that the metal just keeps on giving.

We take a look at three sectors that aluminium is set to disrupt in the coming years. These opportunities will allow producers and consumers to diversify their base and enter new markets.

Fishing farming

At the end of this summer, the Norwegian aluminium giant Hydro and the offshore aquaculture company Ecomerden dived into the fish-farming industry unveiling their new aluminium solution for closed offshore fish farming. The Nordic duo found a way to replace steel with aluminium to produce the floating ring around the fish net.

Aluminium weighs only a third of steel and does not rust. By replacing the heavier steel, aluminium can lead to higher efficiency and lower costs, while also removing the need to manage water pollution caused by steel.

The fish farming industry is set to experience dramatic growth over the next few years, and yet it also poses a clear environmental challenge. Thanks to aluminium’s intrinsic properties, innovative floating collars offer a sustainable solution to the expanding fish-farming business.

Unsinkable yachts

Last year, a Dutch shipbuilder Royal Huisman began construction of what would be the world’s largest aluminium-hulled yacht. Across the Chanel, the British yachtbuilder Sunseeker teamed up this year with Dutch shipyard ICON Yachts to build aluminium superyachts for the first time in its 50-year history.

Thanks to innovative research, porous aluminium is now becoming less dense than water, allowing it to acquire natural buoyancy and therefore making the light metal unsinkable. And yet, the light metal keeps its thickness without losing its strength.

Research and development spur aluminium demand in marine construction, where the metal follows a similar trend to that in the automobile industry. Aluminium’s light weight, high strength, corrosion resistance and malleability, allow to lower the weight of commercial yachts and reduce fuel consumption while also improving safety. With further developments in design and technologies, aluminium has the potential to continue replacing steel as the principle material in shipbuilding.

Low cost robotics

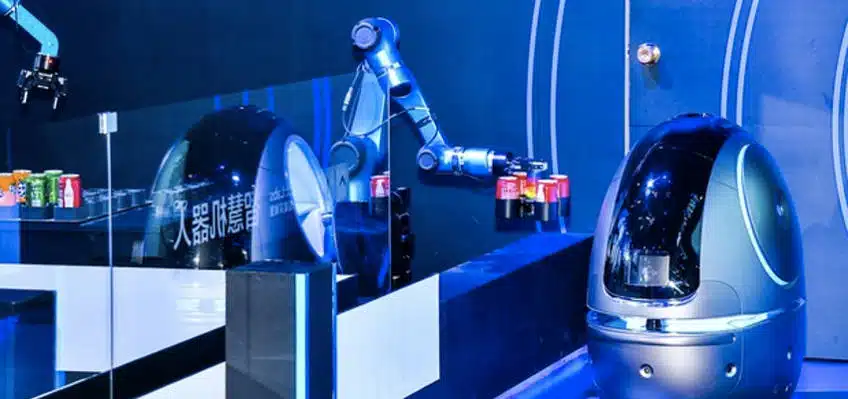

Automation and robotics are disrupting many industries by replacing human workers at factories around the world. Against this backdrop, industrial robots offer many advantages to the aluminium industry to increase efficiency, accuracy and high manufacturing standards. But aluminium is increasingly used in building robotic machines themselves. While automation can be expensive, robots made from aluminium can offer a low cost solution to smaller businesses.

Earlier this month, a German-based manufacturer of energy chain systems Igus, introduced a low-cost delta robot at the 2018 Automatica Convention in Munich. The innovative robot is made of aluminium and plastic materials, and can be easily assembled like IKEA furniture by companies themselves. Lightweight and with low-maintenance requirements, the robot is aimed at small and medium-sized enterprises where the machine can be used for simple assembly tasks.

Another recent addition is Alibaba’s debut of an aluminium service robot that delivers items to hotel guest in China.

Thanks to accelerating growth in industrial and commercial robots, the aluminium industry will be both challenged by the development, but also shape its future.