Innovation is vital for the aluminium industry. As the most abundant metal found on Earth, aluminium offers endless opportunities for consumers in markets ranging from automotive to aerospace, packaging, transportation, industry and defence. From improving existing products to finding new applications for aluminium, this year’s innovative solutions highlight the metal’s significant economic, social, and environmental advantages.

Here are five of this year’s most promising aluminium innovations:

- Carbon-Free Aluminium Smelting Process

American producer Alcoa Corp and Anglo-Australian mining giant Rio Tinto Group revealed in May the world’s first carbon-free aluminium smelting process, calling the breakthrough ““the most significant innovation in the aluminium industry in more than a century”. This revolutionary new method for smelting aluminium produces oxygen and replaces all direct greenhouse gas emissions emitted during the electrolytic aluminium smelting process. Once fully implemented in Canada, Alcoa and Rio Tinto estimate that the new method will eliminate greenhouse gas emissions equivalent to removing 1.8 million cars from Canada’s roads. The duo also launched a joint venture – Elysis – to commercialise the process with a sale of a technology package from 2024.

- Scandium-Aluminium Alloy for Shipbuilding

Russia’s aluminium champion U.C. Rusal announced in March the development of unique scandium alloys. The company’s scientists claim that the alloy – a unique mix of aluminium, scandium and magnesium – meets the unique needs of the shipbuilding industry. The new high strength alloy uses only a third of the scandium incorporated in comparable alloys without sacrificing performance. Cheaper and corrosion-resistant, Rusal’s Al-Mg-Sc alloys are being certified for mass production and will compete with more expensive alloys currently available in shipbuilding, automotive and aerospace markets.

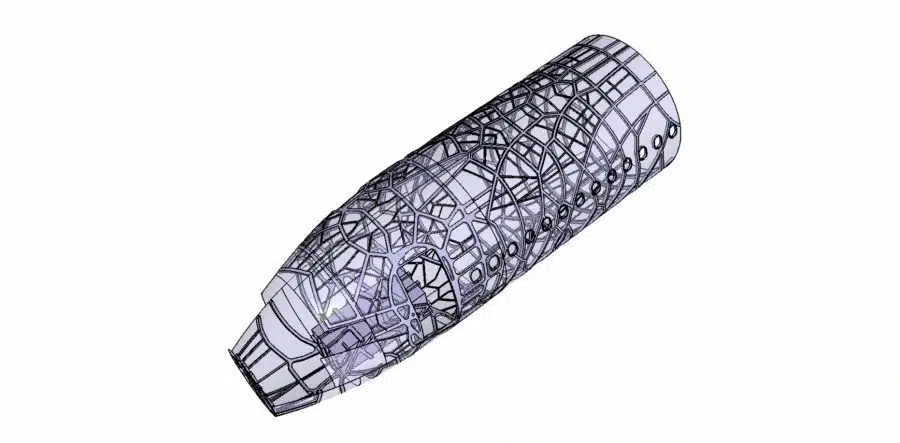

- Metallic self-reinforced fuselage panels manufactured by 3D printing

Four European organisations – Stelia Aerospace, Constellium, Centrale Nantes and CT Ingénierie – partnered up to develop a ground-breaking process for producing self-reinforced fuselage panels by applying aluminium wire to these panels via additive manufacturing. The consortium hopes that this innovative 3D printing technology will eliminate the current time-consuming and labour-intensive method whereby stiffeners are attached to the fuselage panels with fixing screws.

- World’s First All-Aluminium Aircraft Engine

Russian scientists designed an aircraft engine made entirely out of aluminium – the first of its kind in the world. Announcing the breakthrough, the research team pointed out that even the parts exposed to the highest loads – the crankshaft, cylinder barrels and the flywheel – were made of aluminium. These high-stress parts, usually made of steel, were replaced by aluminium thanks to a method whereby a microscopic layer of aluminium oxide is applied on the parts’ surfaces, producing a significantly stronger part. The new all-aluminium engine is 50 kg lighter and now weighs about 200 kg while its power has increased by 10 per cent and its fuel consumption has been reduced by 15 per cent.

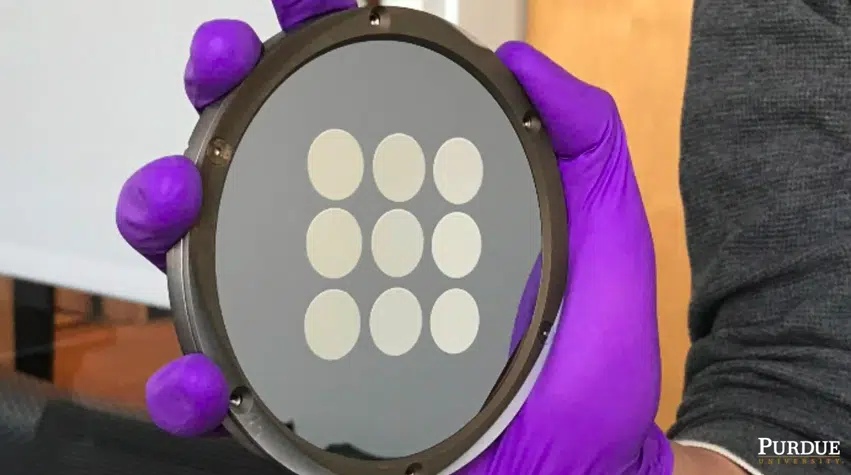

- Super-strong aluminium alloy rivalling stainless steel

New research at Purdue University in the U.S. has led to a discovery of a new aluminium alloy with a strength factor comparable to stainless steel. In their effort to develop high-strength, lightweight aluminium alloys to revolutionise the automobile and aerospace industries, the Purdue researchers have found a way to impart greater strength and ductility by altering the microstructure of aluminium when they introduced distortions in the crystal structure. The research team claims that their lightweight aluminium alloy provides flexibility that stainless steel does not in many applications.